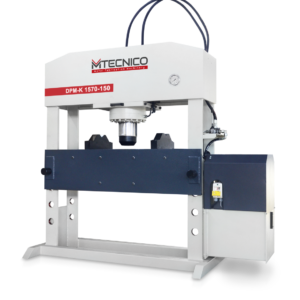

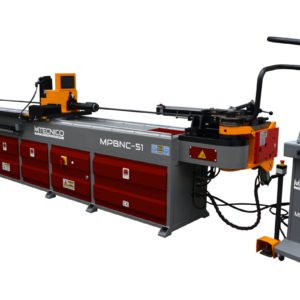

Welded Steel Frames Double Piston Upper Table Sensetive Motorized Angle Setup

- Bending system with Double Cylinder on the upper table.

- Static and dynamic rigidity provided, strong construction with steel frame and upper table material.

- Upper table movement supported by easily adjustable fiber slide bearings.

- Durable balancing spindle and eccentric bearings that aid parallelism.

- Stroke controlled angle adjustment mechanism with mechanical-stop system and motor control.

- High stroke and front opening values that facilitate the use of different bending molds.

- Easy tonnage adjustment with pressure switch and stop at lower stroke point via NC control.

- Hydraulic safety system against excessive pressure rise.

- Double speed working system: free fall, slow bend and fast return.

- Safety enabled foot pedal with emergency stop connected to the NC Controller, enables safe work environment and compatible with CE

- Compact, low maintenance needed HAWE or REXROTH hydraulic system unit located at the top of the machine.

- Service solution with remote connection with European origin SIEMENS and PIZZATO, BALLUF electrical equipments.

- LEUZE brand security system, in the front area enables different forms with learning mode.

- NC control unit, which can write standard 500 programs / 200 lines in each, And easy save and load programs from USB.

- Standard upper and lower molds.

- Motorized X back gauge with high speed and programmed via NC control supported with linear guideways: 600 mm gauge distance and 0.2 mm operating precision,

- Y AXIS Angle Setting by Motor and NC Controller available

- Quick-release PROMECAM upper Die clamping system for partial and quick disassembly. Manual crowning system which can be adjusted with the help of wedge from the upper die holders.

- Easily floating arm control panel.

- Front support arms that can be easily moved with linear slide and bearing systems.

- Tightening and fixing bolts to center the bottom die

- Sensetive prgrammable retreat function on Backgauge to avoid collision