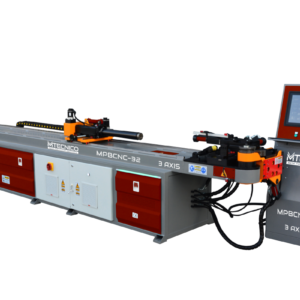

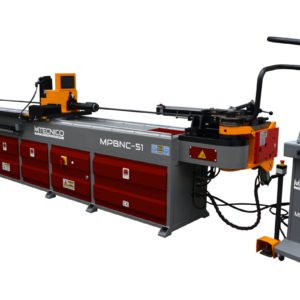

MPBCNC 5 Axis Pipe & Tube Bending Machine

21 ‘’ color touch PC (intel Core i5cpu Ram 8GB)

5 axis servo control (Y, B, C, H, V)

3 axial interpolation movements

Improved 3D Tubular Simulation

3D Machine bending simulation (Collision)

Automatic pipe calculation

Perforating feature

Safety PLC (Omron)

Safety OverEtherCat

Safety mat (750x1000mm)

2D Drawing program (free)

All auxiliary movements are hydraulically operated

(mandrel, clamp die, support, pusher, collet, and shaft carrier)

Linear axle system

Security Switches

Foot Pedal Control

Manual and fully automatic operation feature

Working without mandrel and mandrel feature

Pulling feature while arming

Possibility of bending pipes longer than the machine length (not applicable for all diameters)

Unlimited radius with the rolling system (pushing and bending)

Spiral bending capability (only valid for certain diameters)

Automatic lubricating system

Automatic sled lubrication system

Hydraulic oil cooling system

Programming in YBC mode and converting it to X, Y, Z, and R format.

Line by line deletion feature in the program

Clicking feature in 3D pipe simulation (Y, B, C index viewing)

Converting X, Y, Z, R coordinates to Y, B, C, R format with a button

Conversion of DXF format chicory to Y, B, C format with a button

Conversion of STEP format chicydosian to Y, B, C format with a button

Open and view the file in STL format (compare with step file)

By defining the angle obtained after the first twisting of various materials to the machine, automatic calculation of the difference in the following bends and taking the correct result in the bends